HOLEGAMO RESULTS

- Home

- /

- HOLEGAMO RESULTS

HOLEGAMO RESULTS

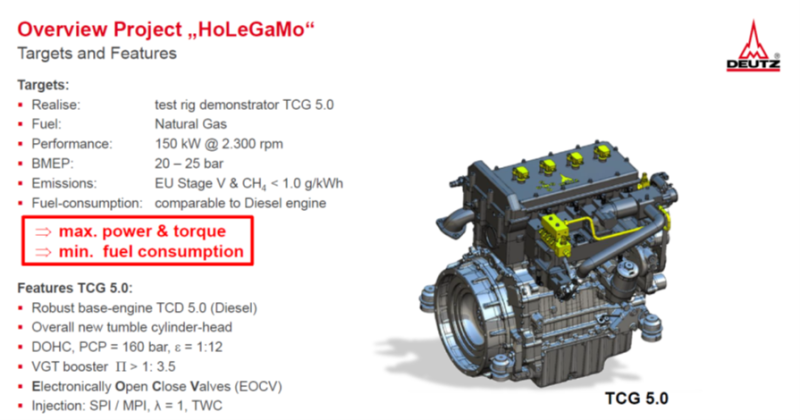

The HoLeGaMo project is initiated to develop a high-performance new generation of gas engines, able to substitute state-of-the-art diesel engines in terms of power, torque and efficiency.

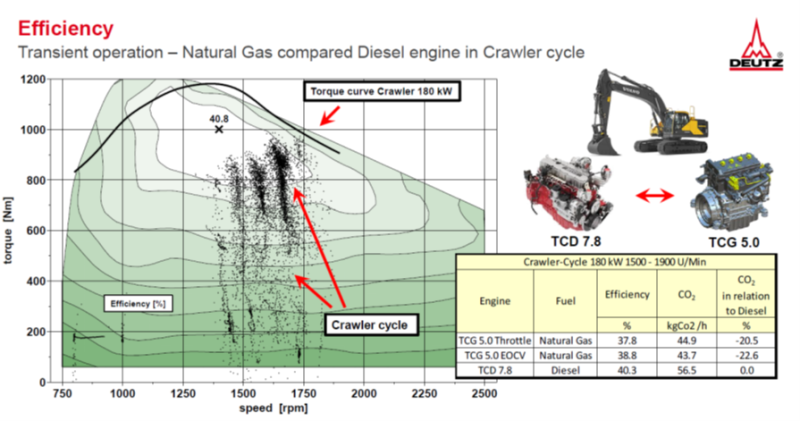

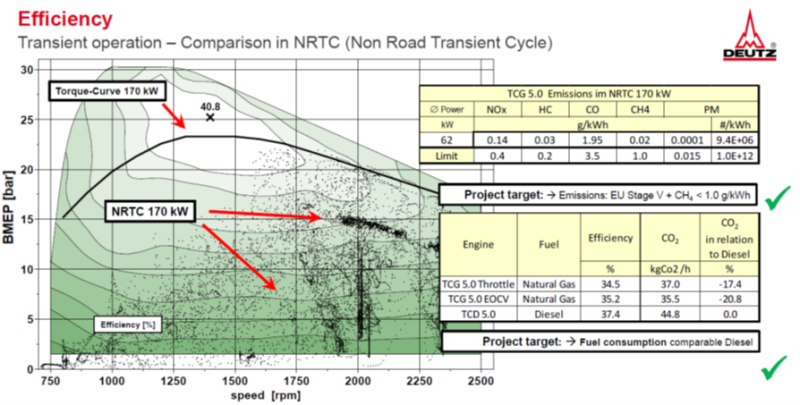

Emission level better than requested by Stage V and at least a CO2 reduction from 20-25% compared with diesel engines are achieved, also in real operation mode, as shown below.

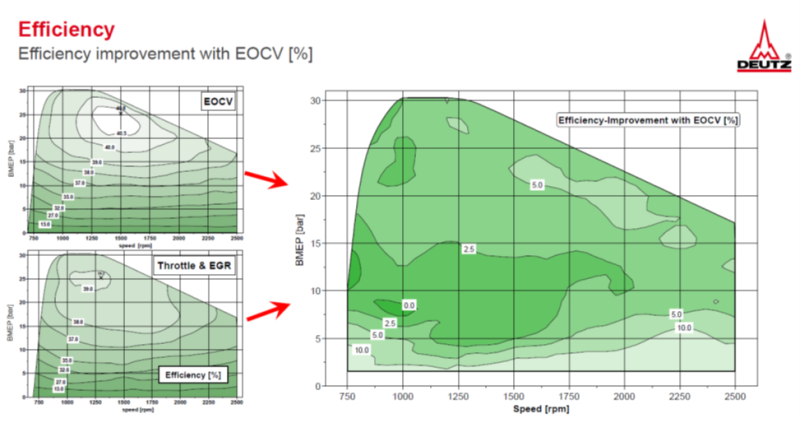

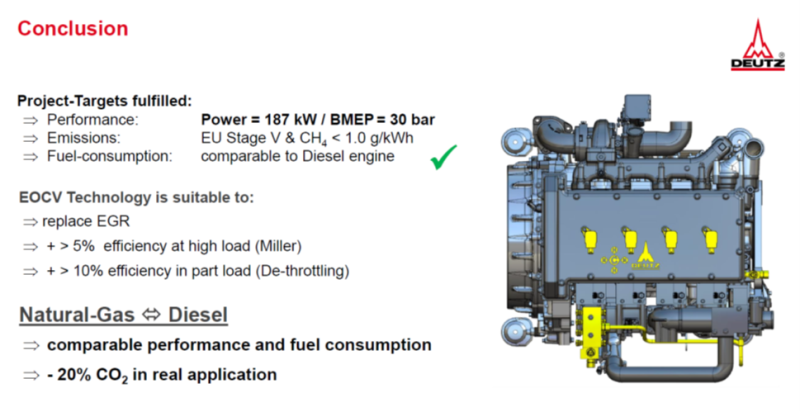

Next to the combustion chamber design with tumble inlet ducts, the NONOX EOCV technology can be seen as the key component to realize astonishing performance/results by de-throttling at part load and the ability of full-variable Miller-timing at high load.

It should be particularly emphasized, that when using NONOX EOCV technology to display the required performance values, exhaust gas recirculation can be omitted. Exhaust gas aftertreatment is reduced to a simple Three Way Catalyst (TWC). The complexity of the engine, as well as the engine packaging, is substantially reduced. Production costs for engine manufacturers as well as Total Costs of Ownership (TCO) for operators become very attractive.

The illustrations give an overview of the objectives and results, as well as an outlook on the advantages that can be achieved when using this technology.

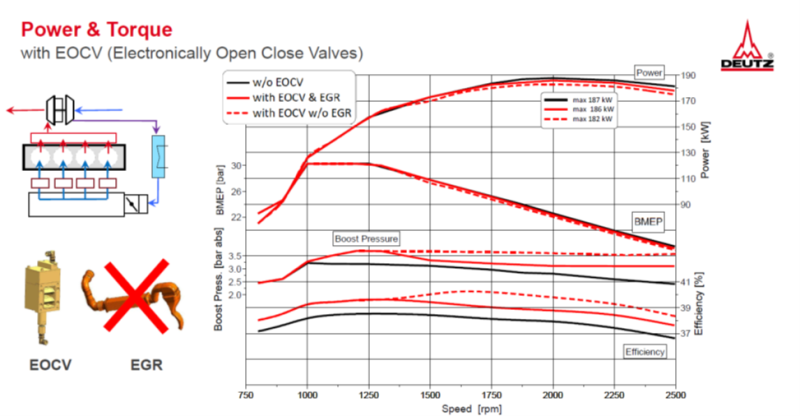

The investigation started with a conventional throttle-controlled engine with an additional high pressure EGR-system to get a reference for the comparison with a NONOX EOCV-controlled, throttle-free load controlled engine. The NONOX EOCV-controlled engine was tested with and without external EGR system. It is a proved fact, that the EOCV-controlled engine without EGR, but operating with fully variable Miller timing, is able to reach the same power and torque as the conventional reference engine with EGR, whilst the efficiency for the NONOX EOCV controlled engine was significant higher over the whole engine map. The figure "Power & Torque" shows the results for the comparison of the throttle-controlled reference engine with EGR, versus NONOX EOCV-controlled engine with and without EGR.

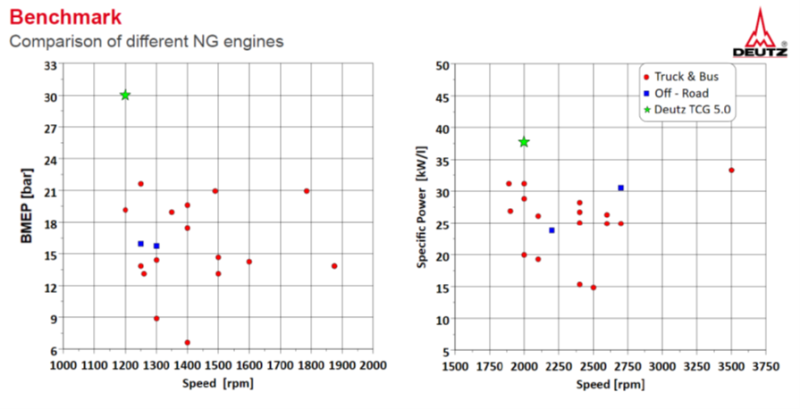

The figure "Power & Torque" compares the TCG 5.0 EOCV engine without EGR with other natural gas engines currently available on the market for commercial ‘off-road’ and ‘on-road’ applications. The figure shows that, with regard to specific power output and mean effective pressure, the ‘HoLeGaMo’ demonstrator displays the highest values compared with any other engine worldwide.

The initial project targets were far exceeded during this first step, but there is potential for more power and torque if the VTG (Variable Turbo Geometry) is optimized.

Pre-investigation show the potential for more than 10% improvement in maximum power and torque output.

The NONOX EOCV technology used in this project was matched to the Deutz 5.0 liter base engine depending on the requested single cylinder displacement from 1,25 liter/cyl and the maximum engine speed of 2500 rpm, but the EOCV technology generally is scalable also to other engine geometries and engine speeds. Actually, a single cylinder displacement from up to 3 liter/cyl and an engine speed up to 4500 rpm is achievable.